Solar Energy Basics

1. What is solar energy?

All forms of energy on earth comes from the Sun except nuclear energy. Solar energy is the energy radiated from the sun, either in the form of light or heat.

2. How is solar energy harvested?

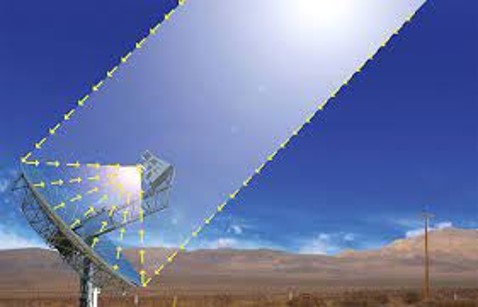

Direct solar energy is generally harvested in two forms: Solar Thermal, and Photovoltaic.

- Solar Thermal: Focused sunlight heats fluid in a reservoir or pipes, fluid boils and produce steam, which drives steam turbine to generate electricity.

Photovoltaic (PV), semiconductor (Silicon) converts sunlight directly into electric energy. PV cells can be Monocrystalline silicon, Polycrystalline silicon, etc. Grape Solar deals mainly with (Mono) PV panels.

Photovoltaic (PV), semiconductor (Silicon) converts sunlight directly into electric energy. PV cells can be Monocrystalline silicon, Polycrystalline silicon, etc. Grape Solar deals mainly with (Mono) PV panels.

3. How powerful is solar energy?

Total power from the Sun’s radiation is about 1.36 KW per square yard at top of atmosphere. When sunlight reaches ground level, its power is reduced to about 1KW per square yard due to atmospheric absorption.

4. How much solar energy can I get where I am?

The NREL (National Renewable Energy Laboratory) provided detailed historical and statistical data of solar resources in the US. Please refer to the Solar Resource Maps and Data page on the NREL website to find out the average sunshine hours of your specific location.

5. How much incentive can I get from the federal. state, and local governments for investing in solar PV?

As of now, the federal government offers progressively decreased solar tax credit through 2024, which provides a 26% tax credit for systems installed in 2020-2022, and 22% for systems installed in 2023. (Systems installed before December 31, 2019 were eligible for a 30% tax credit.) The tax credit expires starting in 2024 unless Congress renews it. For details, please refer to the Homeowner’s Guide to the Federal Tax Credit for Solar Photovoltaics on the DOE website.

State and local governments’ incentives vary by state and location. To find out what incentives are offered by your state and locality, please refer to the Database of State Incentives for Renewables & Efficiency (DSIRE) website.

6. What are the differences between grid-tied and off-grid systems?

A grid-tied solar system connects directly to the electrical grid through a two-way meter typically installed for residential, commercial, or utility applications. These systems are typically installed for financial pay-back while simultaneously contributing sustainable, renewable energy to the grid.

On the other hand, an off-grid system is stand-alone and not connected to the electrical grid. These systems provide power to places where the grid cannot reach conveniently and serve as a great alternative to conventional generators. Popular uses with these systems include but are not limited to: RVs, Boats, Gates, Electric Fences, Remote cabins, Emergency backup and Disaster preparedness.

Charge Controller Q&A

1. What is a Charge Controller and Why it is Needed?

A solar charge controller manages the charging process in a solar system, by regulating the power going into the battery from the solar panels. The primary function of a solar charge controller is to prevent a battery bank from being overcharged or undercharged by a solar array. It also prevents “backflow” when the battery is fully charged.

Charge Controllers also “adjust” the input voltage from the solar panels, and the output voltage to the battery. All of Grape Solar’s charge controllers have the ability to automatically detect and charge 12V or 24V battery systems, while our MPPT 60A controller can automatically detect and charge 12/24/36/48V battery systems.

2. What are the Different Types of Charge Controllers?

There are currently two main types of charge controllers: Pulse Width Modulation (PWM), and Maximum Power Point Tracking (MPPT). Both types regulate the output voltage of the solar panels in order to charge the batteries appropriately. The output voltage and current changes constantly due to time of day, weather conditions, and other environmental factors.

PWM controller is basically a switch between a solar array and the battery bank. This switch regulates the voltage from the solar panels, and will supply a voltage slightly above the battery’s voltage so the battery can be charged. As the batteries are gradually charged, the charging current supplied to the battery from the controller is slowly reduced, to prevent overcharging.

MPPT controller is a more sophisticated device, in that it adjusts its input voltage from the panels constantly to such a point so that it can harvest maximum power from the solar panels. It will then match the panel output voltage to battery voltage to maximize charging efficiency.

While MPPT controllers are more efficient than PWM controllers, they are also more expensive. For smaller solar systems, the difference in using PWM or MPPT controller to charge a battery is much less than in larger systems.

3. Why Do Some Controllers Have No On-Off Switch?

A solar charge controller is connected between the panel array and battery bank, and left alone. There is no need to turn it on and off during its operation. It will automatically sense the charging status of the batteries and will stop charging, or going into float mode, when the battery is fully charged; and it will start charging again during daylight time, if it senses that the battery’s charge is below a certain threshold value.

While an on-off switch might be useful in certain circumstances, for all practical purposes, it is not necessary from a charging perspective. That is why some controllers have this switch, while others do not. Not having an on-off switch does not affect the operation of the charge controller at all, and it would reduce the cost of the controller.

4. What Gauge Wire Should be Used in a Charge Controller?

The wire gauge used in a solar is determined by the current in the circuit, and the distance between the panel array and the charge controller. Each situation is different. The charge controller should always stay close to the battery bank (within 5 feet), to prevent a significant voltage drop from the controller’s out put to the battery bank’s input.

The max wire gauge Grape Solar’s Charge Controllers can accept is AWG#7.

5. What Does the Amp Rating Mean in a Charge Controller?

The Amp rating of a charge controller refers to the rated solar panel charge current, or the maximum input current the controller can handle. For example, Grape Solar’s GS-MPPT-ZENITH-40A controller’s maximum input current is 40 Amps, while the GS-PWM-20A controller has a maximum input current rating of 20 Amps.

6. What Does the Volt Rating Mean in a Charge Controller?

The Voltage rating of a charge controller refers to the battery system voltage it is designed to charge. For example, Grape Solar’s GS-MPPT-ZENITH-40A controller is rated 12V/24V. It means that this controller can work with a 12V or a 24V battery system. On the other hand, our GS-MPPT-ZENITH-60A controller is rated 12/24/36/48V, meaning that this controller can work with a 12V, 24V, 36V, or 48V battery system.

7. Can a 40 Amp Controller charge my 100AH battery?

The short answer is YES. A battery‘s AH rating refers to its capacity, or the amount of energy it can store. It has no correlation with a charge controller’s amp rating. But the Amp rating of a controller will limit the size of your solar panel array, or how many panels you can use together to feed this controller.

8. Can a 60 A MPPT controller handle eight 100W panels? If so, how should I configure the panel array?

Yes, the power rating of our 60A MPPT controller is 900W (800W for older model) for a panel array with a 12V nominal output (1.8KW/24V, 2.6KW/36V, 3.2KW/48V), so it can handle 800W of input. There can be multiple configurations for eight 100W solar panels, depending on the voltage of the battery bank the system is going to charge. Rule of thumb is that the panel array’s output voltage feeding the controller should be above the battery bank’s voltage rating; and the maximum Voc of the panel array should NOT exceed 150 V, which is the maximum Open Circuit voltage the controller can handle. Here are some possible configurations for eight 100W panel, when used with the 60A MPPT controller.

For 12V battery system: 1S8P (8 panels in parallel); 2S4P (2 panels in series, and 4 rows in parallel); 4S2P (4 panels in series, and 2 rows in parallel).

For 24V battery system: 2S4P (2 panels in series, and 4 rows in parallel); 4S2P (4 panels in series, and 2 rows in parallel).

For 48V battery system: 4S2P (4 panels in series, and 2 rows in parallel)

9. Do I need a fuse between the panel and the controller, between the controller and the battery?

While a fuse between a charge controller and battery system will protect the battery in the rare case the controller fails and spits out a huge current, it is not always necessary in smaller, off-grid systems. The controller is designed to determine the appropriate voltage and regulate the current going into the battery, so it is really unnecessary to put a fuse between the controller and battery unless you want double insurance.

A fuse between the panel array and the controller should be used in a situation where the panel array’s maximum output current is close to the controller’s current rating, so a current spike will not damage the controller. If the panel assembly’s maximum output current is far less than the controller’s rated input current, then again it would be unnecessary to use a fuse. For example, when a 12V, 200W panel system is used with a 40A controller, the maximum current the system can produce is about 17 amps, less than half of the 40 Amp rating of the controller. In this situation, it is unnecessary to put a fuse between the panel assembly and the controller.

10. When there is only one fuse available, where should the fuse be connected?

If there is only one fuse available, it should be connected between the panel array and the controller. If a second fuse is available, then it can be connected between the controller and the battery. Of course, if a very expensive LiFePo4 battery is used, and you want to protect the battery more than you care about the controller, then you can also put the only fuse between the controller and the battery. This all depends on individual situation and personal choice. A fuse is going to break the circuit loop when the current in the circuit exceeds the fuse’s rating, so the devices and components downstream are protected from the jolt of the undesired current.

Charge controller is designed to “sense” the battery voltage, and then regulate the controller’s output voltage and current feeding the battery. Unless the controller fails completely in a certain way, a fuse between the controller and battery is really unnecessary in most cases.

11. How do I connect multiple panels with more than one charge controller and batteries?

If there are multiple panels available, or if you intend to add more panels to your solar system to increase its power, there are a few ways of doing it. The key to the configuration depends on the following factors.

Controller Power Rating. The power rating of a controller depends on its nominal input voltage. For example, our GS-MPPT-ZENITH-40A controller is rated 500W for 12V input and 1000W for 24V input. If your the combined power of your solar panels in the system is say, 800W, you have to build a 24 V system in order for this controller to work properly.

Controller Voltage. Once the power rating is determined, you need to look into the maximum voltage the controller can handle. In the example above, the manufacturer states that the Max solar input voltage (Voc, not nominal voltage) should not exceed 100V for the 40A controller. So possible configuration for eight 100W panels could be 2S4P, 4P2S, 4S2P, and 2P4S.

If you have more panels than a single controller can handle, you can also add a controller, and configure the system such that each controller handles a few panels within its power and voltage range. Our MPPT controllers have a communication port, which is designed to synchronize charging of two MPPT controllers on the same battery system. For configuration and connection details, please refer to page 6 of the user manual of our MPPT controllers.

Please always consult a qualified electrician when working with high voltage solar systems.

12. What hardware do I need when I Set up multiple panels?

In addition to panels, charge controller(s) and battery systems, miscellaneous hardware needed to set up a solar panel array depends on multiple factors, including, but not limited to the following.

Parallel, Serial, or Hybrid Configuration? Serial connection between panels does not need additional connectors between panels, as you can simply use the connectors on the panel. For parallel connection between panels, you would need one Parallel Branch Connector Set for each pairs of panels, and each pair of compound panel sets that you want to connect in parallel. For example, if you have eight panels, the number of Parallel Branch Connector Set you would need for each configuration below would be:

- 1S8P (8 panels in parallel): 7 sets

- 2S4P (2 panels in series, and 4 rows in parallel): 3 sets

- 4S2P (4 panels in series, and 2 rows in parallel): 1 set

Distance between Panel Array and Charge Controller. If the distance between your panel array and the charge controller is beyond the reach of the cables provided in the kit, or what you already have, you would need extension cables. Please refer to our Cables and Accessories page to select the right extension cables you need. You will a pair of extension cables to connect the panel array and controller, as each extension cable is built to handle a single line.

Where and How Do You Intend to Mount the Panels. You may also need mounting brackets, if you do not already have existing hardware for mounting the panels. Our Z-Mount set is specifically designed for our panels, and are strong enough to hold the panels in place in tough weather conditions.

Please always consult a qualified electrician when working with high voltage solar systems.

13. Why is my controller displays battery voltage of 13.8V, but the battery capacity does not show 100%?

13.8 V is the float charge voltage of the controller. When the battery has been charge fully, the controller will eventually go into float mode and displays 13.8V. The battery capacity percentage display is actually derived from the battery voltage, and can vary a lot depending on other factors such as temperature, sunlight level at the time of your observation (assuming the battery bank is fully connected to the solar system), and the calibration of the display mechanism of the controller itself, which can also vary slightly from unit to unit. Batteries would never charge or discharge in a linear manner, as soon as discharge takes place, the voltage will drop, and this drop can be significant, thus causing the capacity display to drop below 100% right away. On almost all “capacity meters”, the percentage display is a raw indication of the battery’s charge status, and should never be taken as an accurate measure of the battery’s true charge status or its “capacity” at the time of observation.

A better indication of a battery’s charge status is its open circuit voltage, or Voc. If you measure the Voc of your SLA/FLD/GEL battery bank (without connecting to any load), and the value is at or above 12.7 V, your battery is essentially fully charged.

14. I set my DC Load mode to “17” (Always On), why is my load not lighting up when connected?

When the controller’s DC Load mode is set to “17”, an animated arrow going from the battery to the light bulb should be seen, and there should be a measurable voltage across the load terminals, which should be identical to the battery voltage. But whether there is an adequate current output to run the load depends on the input from the solar panel array’s output, and the load wattage. If the load’s wattage (power rating) is such that the input from the panel array is not enough to run it, then the load (light) will not light up.

A sure way to determine that there is output on the load terminals is to measure the voltage across it. If the measured voltage across the load terminals is the same as the battery voltage, the load terminal is functioning properly.

A better way to power the load is just to connect the load directly to the battery. As energy stored in the battery is consumed by the load, the charge controller will constantly sample the battery’s charge status and charge it appropriately, when there is adequate input from the solar panel array.

Inverter Q&A

1. What is an Inverter?

Our household electricity in the US is 110V AC (Alternating Current), while batteries can only store electric energy in the form of DC (Direct Current). In order to power household AC devices using the electric energy in a battery, DC electricity needs to be “inverted” to AC electricity.

An inverter is a device that converts DC electricity to AC electricity.

2. Do I need an Inverter in my solar energy system?

If your solar system is to be used to power your household appliances, computers, etc., that run on AC, yes, you must have an inverter.

If you only intend to power DC loads, such as LED lights, a small pump, a DC refrigerator, etc., then you do not need an inverter. Whether an inverter is necessary in your system purely depends on the load your solar system will provide power to. Even when you do not need an inverter, you still need to make sure that the voltage rating of your DC appliances is the same as your battery bank’s working voltage.

3. Where do I connect my Inverter?

An inverter’s input always has two leads, a positive (usually Red) and a negative (usually Black). You can simply connect these two leads to the battery’s two leads, positive to positive, negative to negative.

Before you make the connection, you need to make sure that the battery’s voltage is the same as the inverter’s rated voltage. For example, a 12V inverter should only be used with 12V battery systems.

4. Can I use my inverter without a battery system?

Connecting inverter directly to the solar panel’s output should only be considered in grid-tied systems. For a stand-alone, off-grid solar system, it is strongly recommended that a battery system be used together with the inverter. Although it is theoretically possible to connect an inverter to a solar panel, this will only work under very strict conditions, and it will severely limit the duration your power use.

We do not recommend connecting inverters directly to the solar panel in an off-grid system under any circumstances.

5. Can I use a 500W inverter on an 1KW solar panel array?

The power rating of an inverter is not directly correlated to the power rating of the solar panels. Inverter’s power rating only refers to its maximum output power. For example, a 12V, 500W inverter is capable of powering any combined load of up to 500W. You can connect this inverter on a solar system with any number of panels, as long as the battery voltage is also 12V.

Battery Q&A

1. What are the main differences between Lead acid battery and Lithium battery?

There are many differences between a lead acid battery and lithium ion battery. Without going into technical details, here is a summery of main difference, and pros and cons of the two battery types. What battery type to choose really depends in each specific application, the environment that battery is housed, and project budget.

- Lithium-Ion battery is much lighter than lead acid battery. For the same capacity, lithium battery weight about 1/4 to 1/3 of a lead acid battery. In other words, lithium battery has a much higher energy density than lead acid battery by weight.

- Lead acid battery should not be discharged to below 50% of its DOD (Depth of Discharge) on a regular basis, or it will degrade, and its service life will be greatly affected. For lithium battery, this number can be as high as 80%. In other words, For the same capacity battery, lithium battery has much more “usable energy” than a lead acid battery.

- The charge/discharge cycle for lithium battery can be as high as 2000 – 5000, depending on the quality of the battery and typical DOD value, while that for a typical lead acid battery can only be somewhere between 400 – 800 cycles. In other words, Lithium battery has a a much longer service life than lead acid battery, under the same use conditions.

- The advantages of lithium battery come at a cost. Current market price for lithium batteries can be 3 to 4 times as high as lead acid batteries.

2. How many amp hours of batteries are recommended for a 600 watt kit?

The number and capacity of batteries used in a solar panel array depends on what the system is designed for, and the daily average sunshine hours where the panels are installed. A 600W panel array is able to harvest 3KWH of energy with 5 hours of full sunshine in theory, which is more than adequate to fill up three 12V, 100 AH batteries from 50% DOD to full. Lead acid batteries should not be discharge to below 50% DOD regularly, or the service life of these batteries will suffer. For Lithium batteries, this number can be as high as 80% DOD.

Off-Grid System Q&A

1. What voltage are your panels? Will they work with my 12V, 24V or 48V battery system?

Most of our panels are 12V nominal, we also have panels that are rated 24V nominal. Panel output voltage has no correlation with battery system voltage. The charge controller will regulate solar panels’ output voltage, and charge the battery systems. Theoretically all Grape Solar panels are compatible with 12V, 24V and 48V battery systems.

2. How much energy can a 100W panel harvest?

By definition, a panel rated 100 watts can harvest 100WH of energy each hour, or 1KWH of energy every 10 hours under full sun. The amount of energy “produced” by a solar panel always depends on two factors: the size of the panel, and the number of sunshine hours. The same panel will be able to “produce” more energy in summer time than winter time, as we get longer days in summer. Other factors affecting a solar panel’s output include weather conditions, temperature, etc.

3. How should my solar panels be positioned in order to produce the most power?

Ideally, the solar panel should always face the sun in order to maximize its efficiency. For fixed rack mounted panels, the mounted pitch angel of a solar panel is roughly correlated to the latitude of the mounting location. In the continental US, this pitch can be anywhere between 30 to 45 degrees.

4. How do I reach customer and technical support?

You can contact Grape Solar by email: support@grapesolar.com anytime. We shall do our best to respond within two working days.

5. What kind of warranties cover your off-grid solar products?

Each component in a solar system comes with its respective manufacturer warranty. Please check with the manufacturer to obtain accurate warranty information on each product. Since our establishment in 2009, Grape Solar has focused on sourcing system components from reputable manufacturers to achieve the best warranty service experience for our customers.

For Grape Solar’s overall warranty policy, please refer to our WARRANTY page.

6. Will Grape Solar kits provide back-up power to my house during a utility outage?

No, Grape Solar’s off-grid kits are not designed to be connected to the electric grid. Although it cannot provide back-up power to your whole house, it will nevertheless provide adequate power to run your lights, computers, TVs, etc., depending on the size of your battery system.

7. Can your 600W kit work with a 24 V battery, or it only works with a 12 V battery?

This controller that comes with both of our 600 W kit works with either a 12V or 24V battery system. If you intend to have the system work with an even higher voltage battery system, please consider getting our 60A MPPT controller, which works with 12, 24, 36V, and 48V battery banks. Please note that special configuration of the solar panels is needed for the controller to be able to charge higher voltage batteries. The key is that the output voltage of the solar array should always be at or higher than the voltage of the battery system.

Grid-Tied System Q&A

1. How many solar panels should a home have?

This depends on what percentage of your electrical consumption you wish to cover. Because of roof size limitations and budgetary constraints, a typical solar enthusiast will cover one-third to one-half of their electrical consumption with solar energy. A Grape Solar representative or a local installer will be able to run an analysis based on your total annual consumption, factoring in variables such as climate and latitude, to determine the system size that works best for you. For example, a small home in Eugene, Oregon with an average consumption of 700 kWh per month will require a 7.5 kW system to cover 100% of their electrical bill year-round. In comparison, a small home in San Francisco, CA with the same consumption would need a 5.50 kW system to cover 100% year-round. Most homes do not need nor have 100% coverage from solar to achieve payback from a solar system.

2. Will I need batteries to power my home after the sun goes down at night?

Grid-tied solar systems are designed to lower your electricity bill by feeding the grid when power production is higher than immediate usage and draw from the grid when immediate usage is higher than production. Some utilities adopt net metering, where your daytime production is credited to your account at the end of the billing cycle. You would not need a battery bank for your grid-tied system unless you wish to have power in the event of an outage. Battery banks are also useful for those with Time of Use billing structures, storing some of your day time production in a battery bank to use during peak time hours at night. This may also achieve substantial savings on your utility bill. A grid-interactive solar system with battery backup generally costs significantly more than a regular grid-tied solar system due to the cost of the battery and battery-compatible components.

3. How expensive is a typical grid-tied system?

The final cost of your system depends on many variables and requires professional assessment. For example, in 2020 a typical 5.0 kW grid-tied system costs approximately $15,000 for system and installation.

4. Do I need a professional to install them? Do we offer recommendations?

The short answer is yes. Most local and state utilities require a licensed electrician or a licensed solar installer to permit a grid-tied or grid-interactve system. Depending on your location, Grape Solar may be able to refer you to a certified local installer. The installer would then be able to quote you a price for installation labor and guide you through the application process for all local and state rebates and incentives you may qualify for.

5. What kind of warranties cover your solar products?

Each component in a solar system comes with its respective manufacturer warranty. Please check with the manufacturer to obtain accurate warranty information on each product. Since our establishment in 2009, Grape Solar has focused on sourcing system components from reputable manufacturers to achieve the best warranty service experience for our customers.

For Grape Solar’s overall warranty policy, please refer to our WARRANTY page.

6. Should I go 100% solar or should my strategy be a mix of grid + solar?

This answer differs for everyone, as it primarily depends on your personal end goal, local solar incentives and utility billing structures such as tiered pricing or time of use pricing. If your goal is to simply off-set 100% usage from the grid, your budget and available roof space will be the primary limiting factors. If your goal is to have a quick payback period, please contact a Grape Solar representative to help you size the right system.

Miscellaneous Topic Q&A

1. What is the size of Grape Solar cables, and how much current can it tolerate?

All of our cables are 10 AWG, except the Battery to Inverter Cable set, which is 4 AWG; and the Anderson Conversion Cable Set, which is 14 AWG.

When used in solar applications, all voltages produced from our panels are safe in all of our cables. It is the current that has a limit.

10 AWG cable has a theoretical maximum current tolerance of 30 Amps, if used in 12 V systems, that corresponds to 360 Watts, for 24 V system/720 Watt, for 36 V system/1080 Watt, etc… But when used in solar applications, the max current of a cable also depends on the distance between the panel array and the charge controller. The key is not to have a voltage drop significant enough that would affect the operation of the controller.

When the current running through a cable is much higher then its rated/allowed value, it could generate enough heat that melts the insulation layer of the cable, rendering it unusable.

2. Are there diodes in your solar panels to prevent backflow?

Yes, all of our panels have built-in bypass diodes to prevent reverse current and reduce shade loss.

3. Why am I not seeing rated maximum charging current on a sunny day?

In the charging process, you are not going to see full current that is capable of being produced by the panels all the time. This is exactly how the controller is designed. When your battery is not all the way “empty”, especially when it is close to fully charged, a lower charging current will protect your battery from over charging. The controller will continuously adjust the current feeding the battery based on how full the battery is already charged. You might see a charging current close to the panel array’s maximum current under ideal conditions only when the battery bank is very depleted.

If you look at the current display under ideal conditions when the battery is full, you probably will see 0 amps, meaning the controller is going into float mode, and no longer feeds current to the battery.

4. Can I use two IP68 kits to charge a single battery system?

In theory, nothing prevents two or more charge controllers from charging the same battery. Charge controller senses battery voltage continuously, and regulates the charging voltage and current constantly. As the battery voltage gradually rises in the charging process, the controller’s charging voltage and current will be adjusted accordingly, and eventually the charging current will approach zero, as the battery is fully charged.

When two or more controllers are connected to the same battery system, each controller will work independently and follow the same principle. Of course, this is under the assumption that all controllers are set to the same battery type, and their charging parameters are identical. The net effect of using multiple charge controllers to charge a single battery bank is that it takes less time for the battery to be fully charged.

5. Can I hook up two charge controllers to the same solar panel and have them charge different batteries?

No, it is not a recommended practice to feed the output of one panel into two controllers. Typically, solar charge controllers are designed to handle the output of multiple panels, not the other way around. For residential off-grid systems, if there is a need to charge two separate battery systems, getting another solar kit is the safest and most efficient option.

6. If I need to charge my battery with a generator, do I need to disconnect my solar system from the battery?

For small battery systems (RV or household backup battery) connected to a solar charge controller, there is no need to disconnect the controller from the battery when charging the battery with a generator. Most commercially available charging systems (Controller or generator) work in such a way that when the battery voltage reaches a preset threshold in the charging process, charging would stop. But if you really want to feel assured, it does not hurt to install a switch between the battery and the controller, so you can cut off the solar system when using the generator.

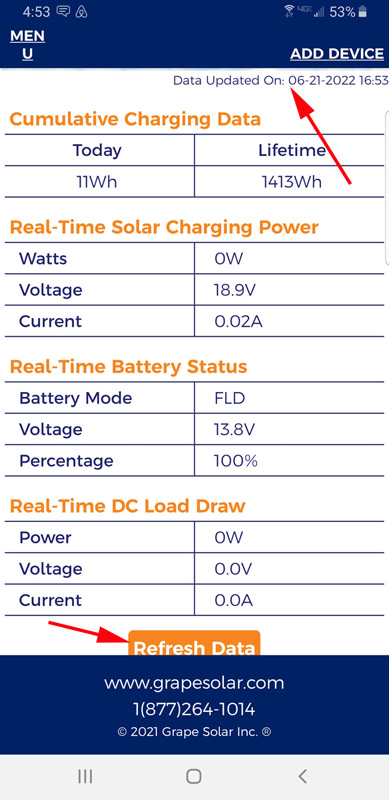

7. How do I use Grape Solar's mobile app to monitor my solar system?

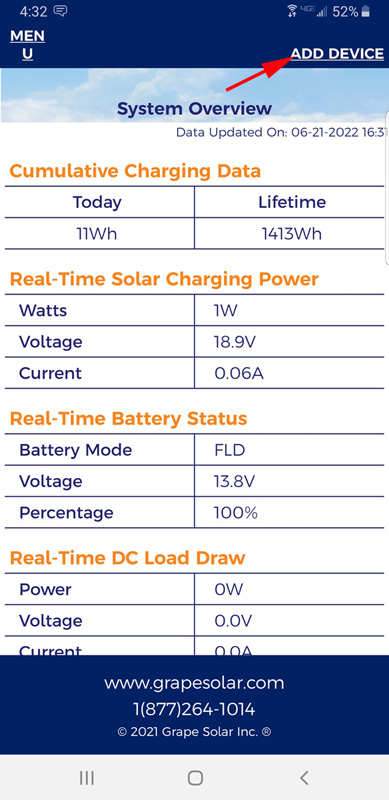

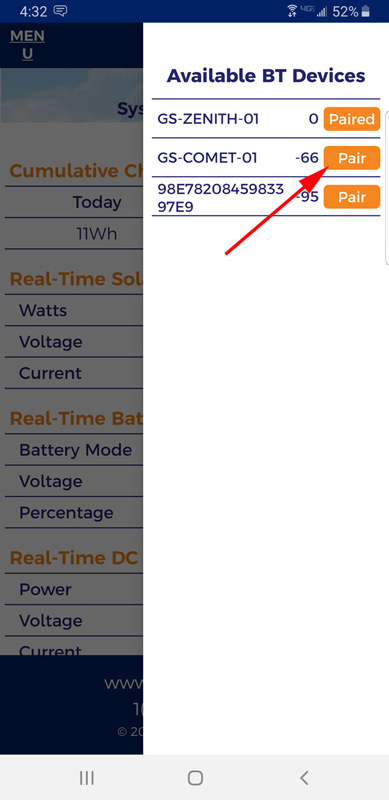

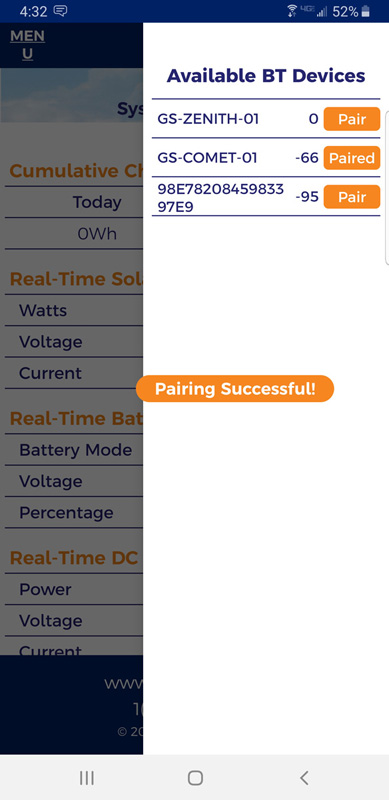

Grape Solar’s mobile app is designed to monitor the solar system by communicating with the Grape Solar charge controller via blue tooth. Please follow the steps below to use this app.

- Download the app from the Apple App Store or Google Play Store, depending on your operating system

- Stay close to the charge controller, open the app, tap “ADD DEVICE” on the upper right corner while the controller is in operation

- Find your controller and tap “Pair”, system will show “Pairing Successful” when the controller is paired with your phone

- Start monitoring, you can tap “Refresh Data” to get the latest data from the controller, system will show data update time

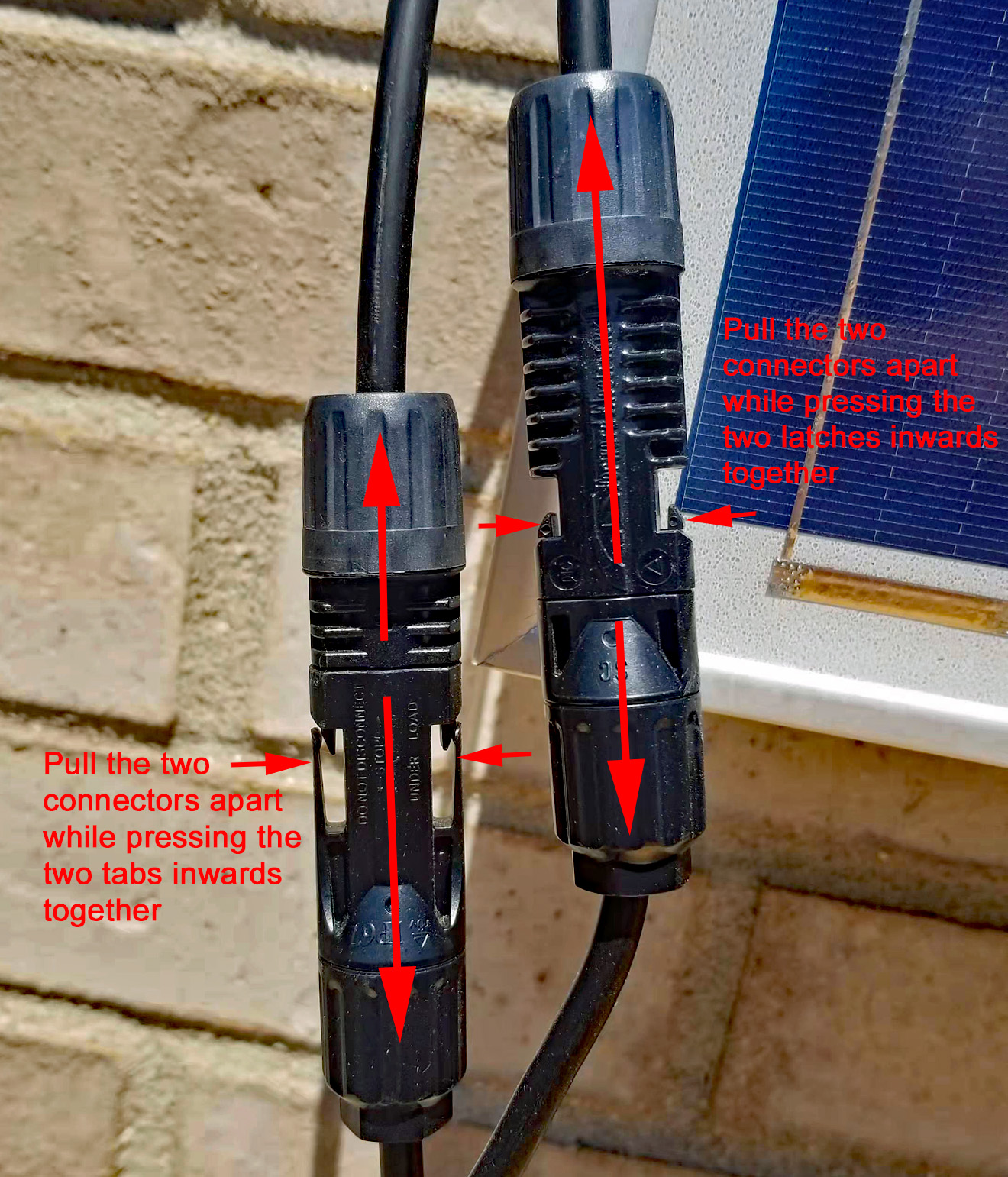

8. Are special tools needed to disconnect the standard PV connectors from each other?

No special tools are needed to disconnect/disengage the solar panel connectors, it requires pushing the latches inward while pulling the connectors apart from each other, as shown in the image below.

9. How do I connect multiple panels in parallel or Series?

When multiple panels are used in a solar array, they can be connected in parallel, in series, or a combination of both, depending on how your panel array is designed and configured. For details of panel connection, please refer to the Panel Connection Guide.